By achieving energy-efficient dehydration, this equipment not only eliminates clogging issues but also results in substantial cost savings in sewage plant construction. It finds extensive application in various sectors, including municipal wastewater treatment, food and beverage industry, chemical industry, mining and quarry wastewater treatment, tannery operations, paper and pulp processing, electroplating facilities, textile dyeing processes, power generation plants, and more.

Working Principle

Sludge dewatering press is equipped with unique technology, which allows dewatering sludge while automatic self-cleaning the screw body. This enables stable and constant dewatering without clogging.

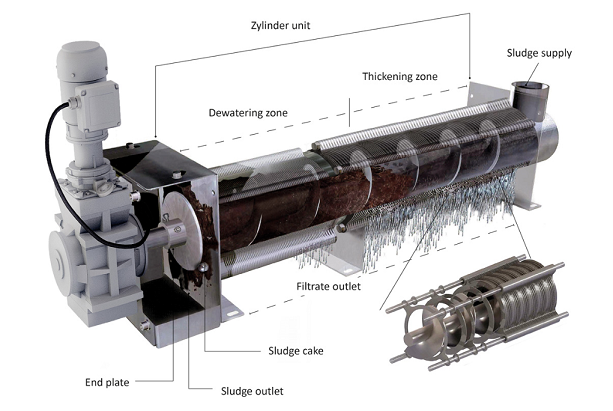

This innovative filtration device comprises fixed rings, moving rings, and a central spiral mechanism. It harnesses the principle of screw extrusion, creating substantial extrusion pressure through variations in screw diameter and pitch. This pressure, combined with the minute gap between the moving and fixed rings, facilitates efficient sludge extrusion and dehydration.

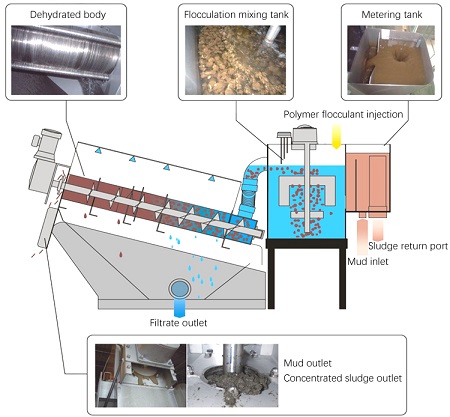

The sludge enters the system through the feed inlet, then proceeds to the metering tank, followed by the flocculation mixing tank, and ultimately reaches the dewatering tank. Inside the dewatering tank, the spiral shaft's rotary vane propels the sludge while gradually reducing the pitch. This process increases pressure differentials, effectively dehydrating the sludge, causing water to exit through both fixed and moving rings.

Furthermore, the device features a self-cleaning mechanism between the fixed and moving rings, preventing any blockages in the filter and maintaining optimal performance. Once the sludge reaches complete dehydration, the sludge cake is discharged through the discharge port, driven by the propeller shaft.

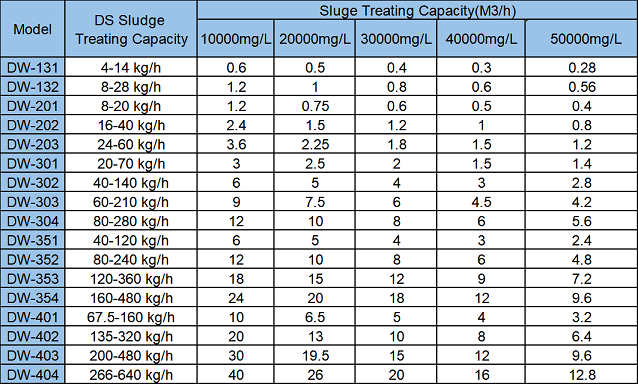

Model Selection

Copyright © 2025 Bluepurell Co.Ltd.